High Pressure Processing

High pressure treatments

What is HPP technology and how does it work?

HPP, or High Pressure Processing technology, is an ultra-modern food treatment and preservation process where treated productsare subjected to extreme hydrostatic (water) pressure, which not only increases the shelf life to a great extent, but also greatly improves other organoleptic and food safety properties, while no heat treatment or other preservatives are required to ensure long-lasting freshness of the products. application of the data.

The treatment works primarily on microorganisms and enzymes based on protein denaturation, structural changes, cell deformation and membrane damage. During treatment, solid or liquid foods are exposed to pressures between 100 and 800 Mpa (By comparison, the marianna trench with a depth of 11,000 m is dominated by a pressure of 167 MPa).

The technique has many advantages, such as the preservation of good color, aroma, vitamins and nutritional value, the often favourable change in stock (e.g. softening), or the fact that food can be treated in packaged form, so the possibility of post-infection can be completely excluded. The technology is environmentally friendly and almost waste-free, and the pressure in sealed packages is instantaneous and in its entire mass, i.e. the effect of the treatment is independent of the size and shape of the food, unlike other preservation technologies.

More about https://en.wikipedia.org/wiki/Pascalization

Environmentally friendly technology

Our HPP equipment is extremely environmentally friendly. For its operation, it uses only electricity and water during treatment.

Benefits of HPP technology

Higher quality

The product retains its freshness, taste, aroma and nutritional value at the time of manufacture, which means a much higher quality than traditional preservation processes.

Maximum food safety

When handling packaged finished products, pathogens (Listeria, Salmonella, Vibrio, Norovirus, etc.) are destroyed, which greatly increases food safety and minimizes re-infection!

Long-term fresh produce

It extends the shelf life of the product, thereby increasing consumer satisfaction. (Freshly squeezed fruit and vegetable juices retain their warranty for up to 70 days).

Decomposing material exemption

It drastically reduces the amount of decomposing substances at microbiological level, which means higher quality during shelf life.

Preservative exemption

The use of various preservatives can be avoided or reduced in large proportions, thereby increasing the proportion of natural, additive-free foods.

Innovative use

The innovative process increases the competitive advantage by preserving foods that have not previously been preserved, e.g. by heat treatment.

Juice manufacturing and HPP treatment

Inactivation of microorganisms and increase shelf life

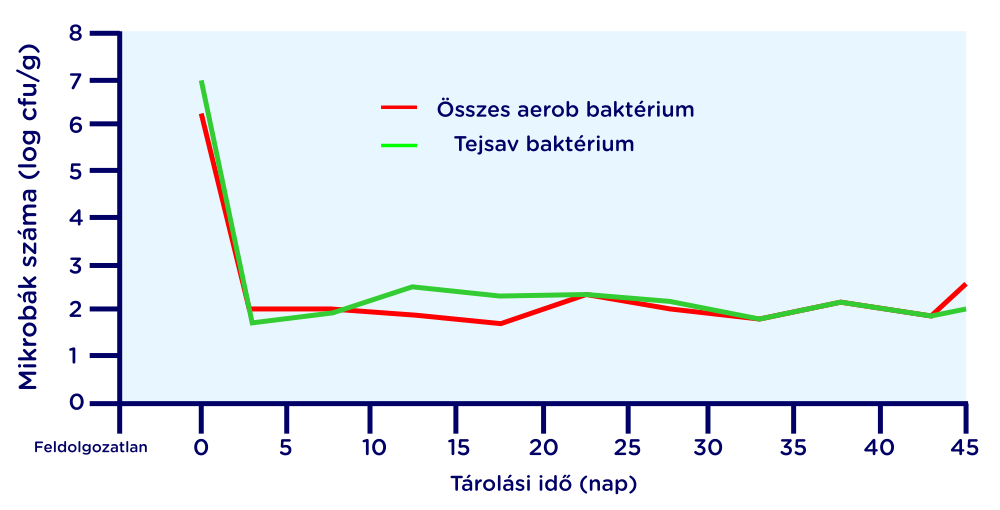

High pressure between 400 MPa/58 000 psi and 600 MPa/87 000 psi for a period of 1 to 5 minutes reduces the number of microorganisms causing food degradation (yeasts, moulds, lactic acid bacteria,) E. coli, Listeria, Salmonella, Cryptosporidiumin) in fruit and vegetable products. The shelf life increases by 3 to 10 times compared to non-HPP products under the same storage conditions. HPP treatment not only increases shelf life at the microbiological level, but also preserves organoleptic quality for much longer, as it inactivates microorganisms that cause food deterioration. HPP processed products retain their freshness for a much longer period of time.

Total aerobic and lactic acid bacteria in guacamole (600 MPa, 3 minutes) treated with HPP technology stored at 4 °C.